Production Lot Sizing Problem with the Lead Time

Abstract

The issue in lot sizing problem is to plan production processes, so that mean the production quantities must be equal to customer demand quantities such that the inventory cost and setup production cost is minimized. In this work, we use the model Multi Level Capacitated Lot Sizing problem with consideration the Lead times, which means that the problem of finding a feasible solution is complex. For this, we propose a new formula in comparison with the classic model. The efficiency of the new formula is demonstrated and infeasible solutions are solved by a heuristic method that's based on Lagrangian relaxation. Computational tests conducted in 1000 instances with up to 40 components and 16 periods have shown that optimal solutions were obtained on average 96.43% of the large instances. For the improvement of the best solution, the heuristic is able to find the efficiency with 97.62% on average. The solution quality is evaluated through initial iterations, the average solution time provided by Lagrangian relaxation is less than 0.43s.

Downloads

References

Almeder.C, R.Traxler al. 2014, Lead time considerations for the multi-level capacitated lot-sizing problem, European Journal of Operational Research 000 (2014) 1–12.

Almeder, C.,&Almada-Lobo, B.(2011). Synchronization of scarce resources for a parallel machine lot sizing problem. International Journal of Production Research, 49(24),7315–7335.

Almeder, C.(2010). A hybrid optimization approach formulation level capacitated lot sizing problems. European Journal of Operational Research, 200,599–60

Bel G., Aide à la conception et à la conduite de systèmes à événements discrets : Application aux systèmes de production, Habilitation à diriger des recherches, Université Paul Sabatier, Toulouse, Mai 1998.

Berretta, R., Franca, P., Armentano, V., 2005. Metaheuristic approaches for the multilevel resource-constraint lot-sizing problem with setup and lead times. Asia - Pacific Journal of Operational Research 22 (2), 261–286.

Billington, P., McClain, J., Thomas, L., 1983. Mathematical programming approach to capacity constrained MRP systems: Review, formulation and problem reduction. Management Science 29, 1126–1141.

Buschkuhl, L., F. Sahling, S. Helber, and H. Tempelmeier (2008). Dynamic capacitated lot sizing a classification and review of the literature on big bucket" problems.

Buschkühl, L., Sahling, F., Helber, S., Tempelmeier, H., 2010. Dynamic capacitated lot-sizing problems: a classification and review of solution approaches. OR Spectrum 32, 231–261.

C. A. Kaskavelis et M. C. Caramanis. Efficient lagrangian relaxation algorithms for industry size job-shop scheduling problems. IIE transactions, 30(11):1085–1097,1998. 28

Chen, H. et Chu, C. (2003). A lagrangian relaxation approach for supply chain planning with order/ setup costs and capacity constraints, Journal of System Science and Systems Engineering.

Comelli, M., M. Gourgand et D. Lemoine, 2008. A review of tactical planning models, Journal of Systems Science and Systems Engineering, Vol.17(2), pp 204-229.

D.-Y. Liao, S.-C. Chang, K.-W. Pei et C.-M. Chang. Daily scheduling for R&D semiconductor fabrication. IEEE transactions on semiconductor manufacturing, 9(4):550–561, 1996. 28

Fisher, M. L. (2004). The lagrangian relaxation method for solving integer programming problems. Management science 50 (12 supplements), 1861–1871.

IBM ILOG AMPL, Version 12.2. User’s Guide Standard (Command-line) Version Including CPLEX Directives. May 2010.

J. M. Swaminathan. Tool capacity planning for semiconductor fabrication facilities under demand uncertainty. European Journal of Operational Research, 120(3):545– 558, 2000. 26, 28, 42, 44, 45, 71, 90

Nascimento, M. C. V., M. C. G. Resende, and F. M. B. Toledo (2010). GRASP with path-relinking for the multi-plant capacitated lot sizing problem. European Journal of Operational Research 200, 747–754.

Razki H. and Moussa A. (2017). Langrangian Relaxation of Multi Level Capacitated Lot Sizing Problem with Consideration of Lead Time . In Doctoral Consortium - DCORES, ISBN , pages 12-19

Sambasivan, M. and S. Yahya (2005). A lagrangean-based heuristic for multi-plant, multi-item, multi-period capacitated lot-sizing problems with inter-plant transfers. Computers and Operations Research 32, 537–555.

Toledo, C. F. M., L. de Oliveira, R. de Freitas Pereira, P. M. Fran¸ca, and R. Morabito (2014). A genetic algorithm/mathematical programming approach to solve a two-level soft drink production problem. Computers &Operations Research 48, 40–52.

T.-R. M. Chen et T. Hsia. Scheduling for ic sort and test facilities with precedence constraints via lagrangian relaxation. Journal of Manufacturing Systems, 16(2):117– 128, 1997. 28

VOLLMANN, T. E., W. T. BERRY, AND D. C. WHYBARK (1988), Manufacturing Planning and Control Systems, 2nd ed., Dow Jones, Richard D. Irwin, Homewood, IL.

TRANSFER OF COPYRIGHT

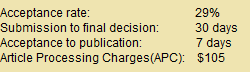

JRBEM is pleased to undertake the publication of your contribution to Journal of Research in Business Economics and Management.

The copyright to this article is transferred to JRBEM(including without limitation, the right to publish the work in whole or in part in any and all forms of media, now or hereafter known) effective if and when the article is accepted for publication thus granting JRBEM all rights for the work so that both parties may be protected from the consequences of unauthorized use.